Walnut Shell Blasting

Maintain your BMWs Health...

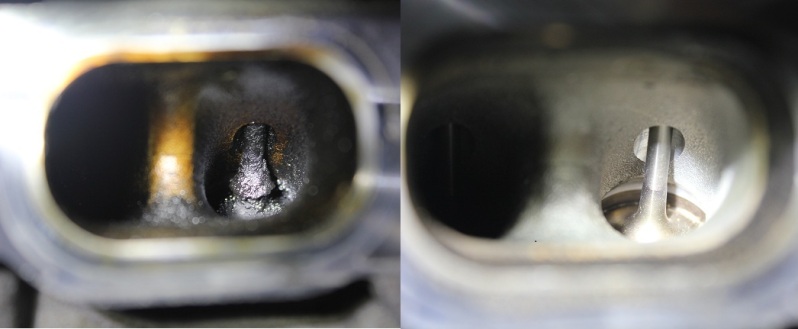

Most modern engines have direct fuel injection systems including both BMW diesel engines and more recently (around 2007) BMW & MINI petrol engines. ‘Direct injection’ describes the method of fuel addition to the engine, and possesses several advantages over conventional fuel injection. Such as, improved fuel consumption, reduced emission levels at low loads and higher power yields. This method does however, mean that the inlet valves, over time, become carbonized (i.e carbon build up) due to the constant contact with ‘blowby’ gases though the breather system. Conventional injection did not suffer this due to the fuel constantly soaking & therefore cleaning the inlet valves. The carbonized inlet valves of direct injection engines will, in time require cleaning to remain efficient. Increased oil consumption, erratic idle, cylinder misfires and reduced performance are common symptoms of heavy accumulation of carbon and oil.

Smoother idle, improved fuel consumption.....

Walnut shell blasting is a neat & very efficient method for cleaning carbonized inlet valves. An alternative to stripping the engine which is costly & time consuming, this handy tool, injects walnut shell particles at high velocity directly onto the carbon deposits. The carbon is literally blasted off without causing damage to the material of the valve. This is the reason for the use of such an obscure product, walnut shells, hard enough to displace the carbon but not too hard as to cause any damage to the valves. The process will give noticeable results including smoother idle, improved fuel consumption and potential increased engine power.